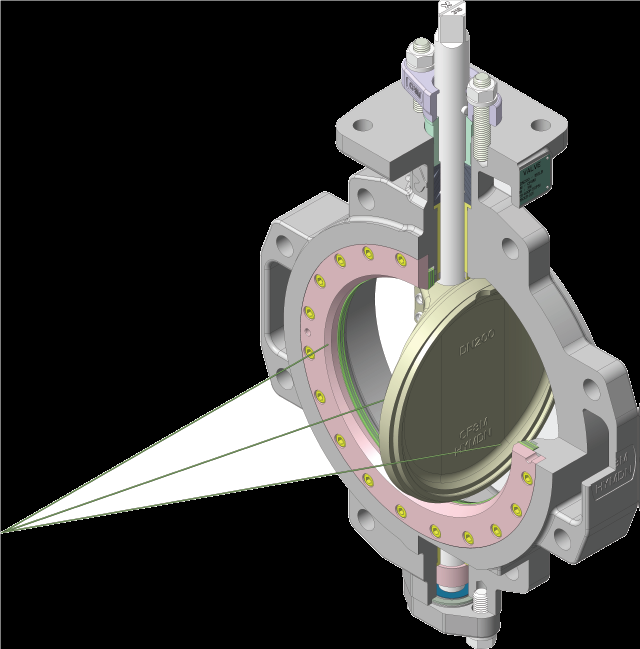

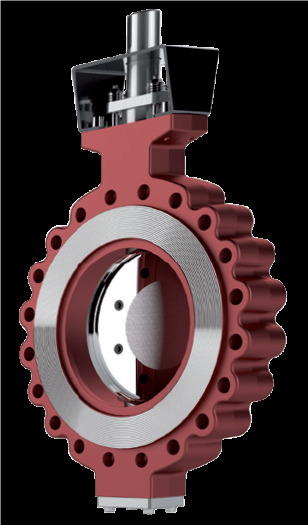

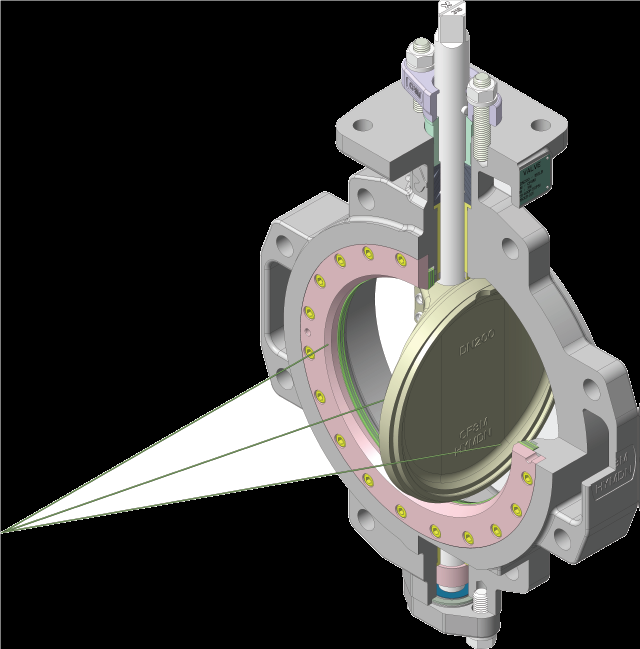

Gland Flange : A fully adjustable two-piece gland flange to make sure an even packing load over 360 °

Anti-Blow-Out system : Protecting stem blow-out caused by pressure.

Gland Bush : Standing alone with Gland Flange, preventing uneven down-pressure on gland packing.

Gland Packing : Multiple materials are available to use. Performance is compliance with API 598’s testing pressure.

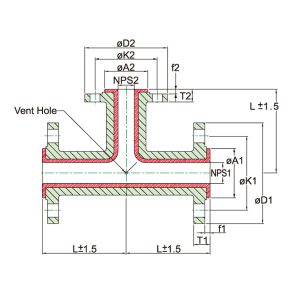

Valve Seat : Bi-direction zero leakage design. Use Solid or Laminated Metal.

Taper Pin : Tangentially positioned half in disc and half in stem to eliminate potential of failure.

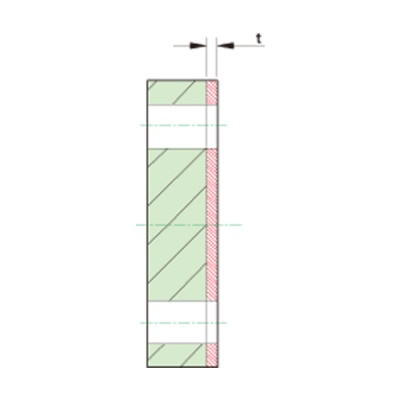

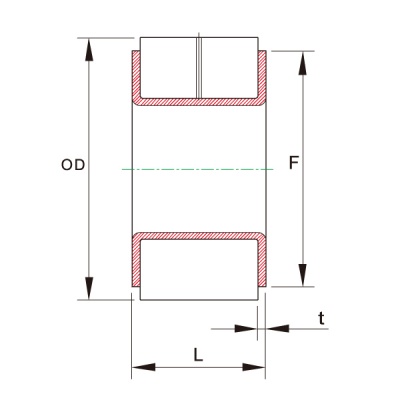

Retainer Ring : A screw-fixed design retainer ring. This deign can be used in the end of pipe system. Surface roughness is 125-200AARH.

Thrust Ring : Use 316 as material.

Position in bottom of stem for preventing incorrect stem shift.

Bottom Cover : Use rigid 316 as material to prevent abnormal leakage.

Bottom Gasket : Uses Sprial wound Gasket as material.

Valve Stem : Use stainless-steel with hard chrome plated. A strong and rigid one-piece-stem design which largely increase overall strength. Stem and corresponding components size are all compliance with ISO 5211. Stem material and disc position is marked on the top of stem.

Bush : Uses Nitrided 316 stem bush. Has excellent working temperature, strength rating, and low friction factor.

Bush Protector : Using graphite. Resisting fluid debris into the valve to ensure smooth operations.

Valve Disc : Use stainless-steel with ENP or Stellite 21 treatment. An anti-corrosion, streamlined design with great enhancement on lowering noise and turbulence.

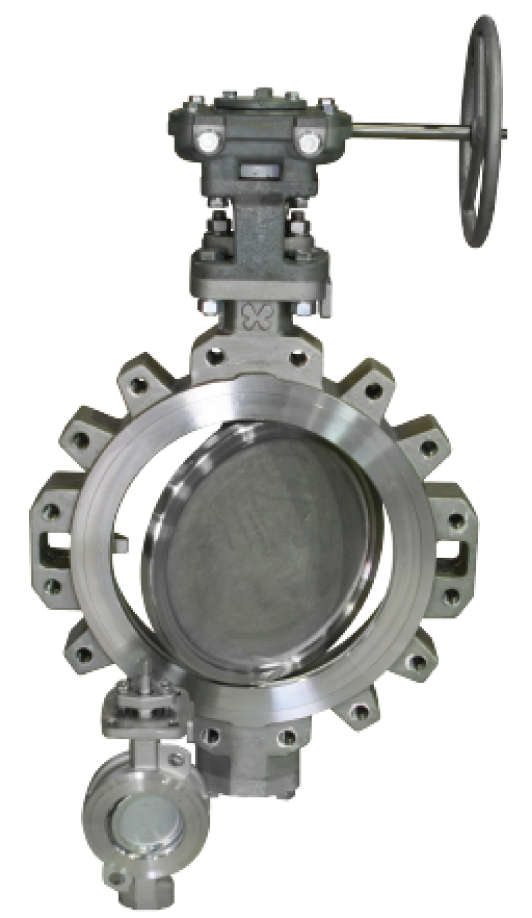

Valve Body : Compliance with API 609 & ASME B16.34. In order to make valve context intuitive and straightforward, an additional name plate is designed to mark detail information

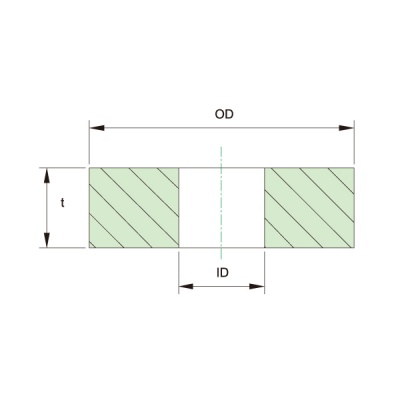

Seat Gasket : Uses Sprial wound Gasket to keep zero-leakage under any kind of pressure or temperature.

Thrust Plate : Use Nitrided stainless-steel 316 to reduce operating friction between stem and bottom cover.