“Top-Entry” Ball Valve – Wuzhou Valves

MAIN FEATURES

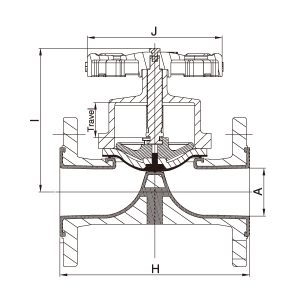

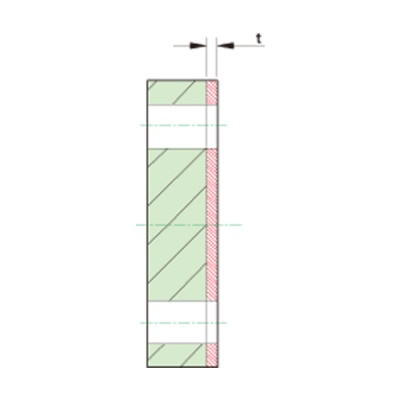

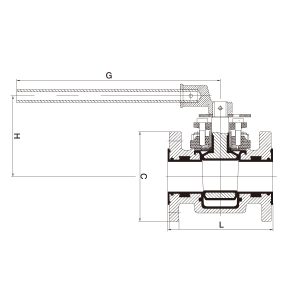

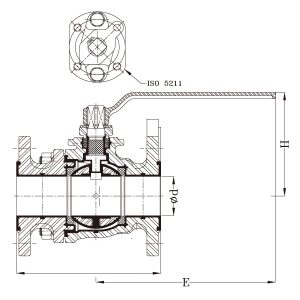

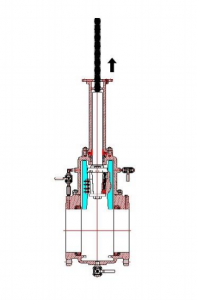

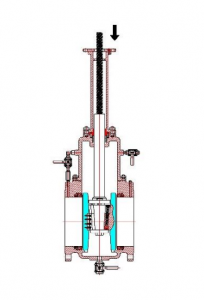

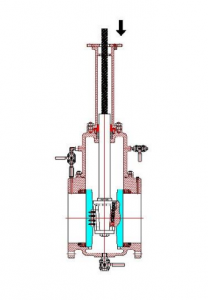

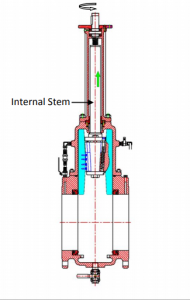

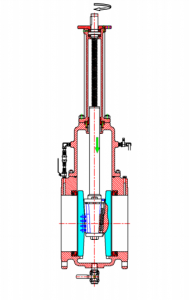

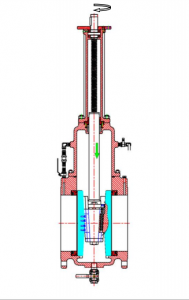

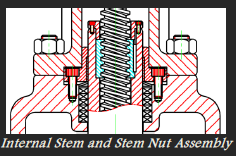

The top-entry ball valve is designed as an integrated valve body. Its support and ball rod fixed by an upper-assembled pivot and an integrated pivot respectively and the integrated high-strength ball rod ensure an accurate ball positioning. The unique technology of retractable valve seat is adopted, realizing online replacement of valve stem, valve stem seal rings, metal valve seats and preloaded springs.

Design Features

The ball valve are designed in accordance with ISO14313、API 6D、BS 5351、GB/T 19672;

Simple structure with good tightness and small torque;

One piece type body;

Have reduce bore and full bore with the minimum flow resistance (zero actually);

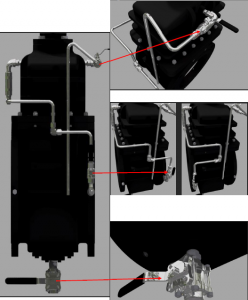

Emergency sealant injection;

Cavity pressure self relief;

Low emission packing;

Fire safe, anti-static and anti-blowout stem design;

Valve seat function DBB, DIB-1, DIB-2;

Optional extended bonnet.

Product Range

Body material: carbon steel, stainless steel, alloy steel

Nominal diameter::2″~60″(DN50~DN1500)

End Connection: RF,RTJ,BW

Pressure range:Class150~2500(PN10~PN420)

Working temperature:-46℃~+200℃

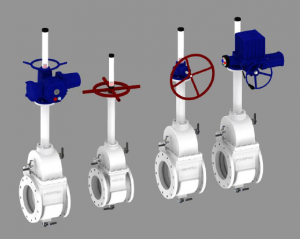

Operation : wrench, worm gear, electric, etc.