PFA Lined Pipe – Bueno

Specifications

-

- Chemical Processing

- Water Treatment

- Power Generation

- Ultrapure Chemical Processing

- Use for acids, caustics, bleache, and etc.

Product Description & DesignPFA lined Pipes and PFA lined Fittings

Our metal pipes and fittings for PFA lining are either manufactured via casting or through welding seamless pipes.

The available dimensions are 1/2″ ~ 6″, the thickness of metal pipe and metal fittings for PFA lining are in accordance with schedule 40.

The default materials used are as follow, if unspecified,- Meterial

Carbon Steel Stainless Steel Fittings Seamless Pipe ASTM A234 grade WPB ASTM A403 Cast Steel ASTM A216 grade WCB ASTM A351 Pipe Seamless Pipe ASTM A587 or ASTM A53 grade B ASTM A312 - Specifications

Fittings ASME B16.5 CLASS 150 Pipe ASME B36.10 Flange

The default materials used are as following, if unspecified:- Materials

- In accordance with ASTM A105 (if the fitting i made via casting, then the flange will be cast as part of the fitting)

- In accordance with ASTM A182

- Specifications

- ASME B16.5 Class 150

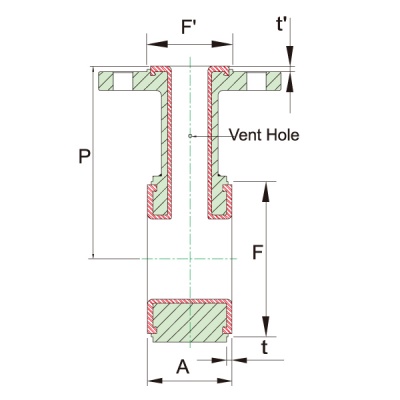

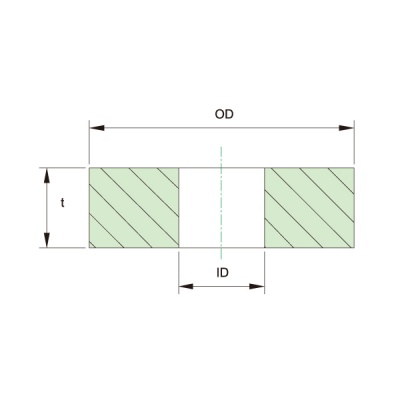

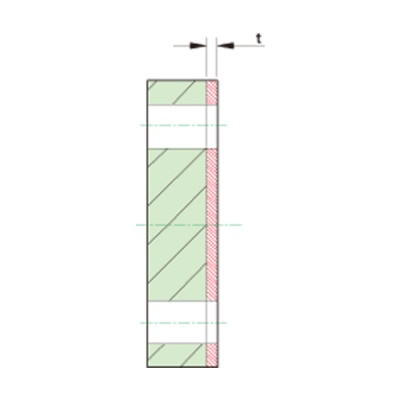

PFA Lining ThicknessPFA ( Perfluoroalkoxy)Pipe 1/2″ ~ 2″ about 3mm PFA Lining Thickness 2 1/2″ ~ 6″ about 4mm PFA Lining Thickness Fitting 1/2″ ~ 4″ about 3mm PFA Lining Thickness 2 1/2″ ~ 6″ about 4mm PFA Lining Thickness WeldingIn accordance with ASME Boiler and meets the requirements of Pressure Vessel Code, clause nine.Exhaust HoleEach PFA lined pipe and PFA lined fittings has at least one 2mm diameter exhaust hole in order to release the gast trapped between the liner and the metal part. If the pipe exceeds 500mm in length, it will contain at least two exhaust holes. Reducing flanges don’t have exhaust hole.Coating- Thickness is approximately 110µm.

- The standard application of coating contains two layers:Special requirements for coating are available upon request

- Base paint

- Surface paint

Procedures of Oil and Water-Free treatment- AK3 oil removal (Heated)

- Acid neutralization

- Cleansing using RO Water

- Dry nitrogen air spraying

- Channel seal packaging

TestWe uphold a full inspection policy that requires all finished PFA lined pipe and PFA lined fitting to pass the following test before shipment. Other methods of testing can be done upon customer demand.- Pressure Test: Applies max operating pressure*1.5 Air

- Tight Test: Applies mzx operating pressure*1.5

- Spark Test: 15000~20000VDC

- Water and Oil Free Test:

- Cleansed according to the standard of 1.0mg/ft (MAX)

- We will start manufacturing after the sample has been approved by our client.

- We can also provide notarization from authorities upon request.

- Coating: We pick products on random for testing with paint thickness tester.

- Appearance:

- Each piece is checked for bubbles, pinholes, or other impairing defects before the lining process. Minor blemishes are processed during the coating stage.

- Blistering and paint peeling are not allowed after coating.

Pressure Test Spark Test Coating TestPacking and Storage- The exhaust holes are sealed before packaging.

- Packaging

- The ends of normal pipes and flanges are sealed with plastic plates to prevent damage to the PFA liner.

- For water and oil free lined PFA lined pipes and PFA lined lined fittings, the two ends are sealed with adhesive-free tapes (alternatively, the flanges can be sealed by plastic bags), and covered with end caps to prevent damage to the PFA liner. Before storage and shipping, the products are labeled, numbered, and sorted according to order number, charge number, and content. After being properly ordered, they are collectively stored or shipped. The products are packaged with wooden crates when shipped; in addition, the interior of the crate contains a large plastic seal to prevent water and vapor permeation.

Material List

| Parts | Carbon Steel | Stainless Steel |

| Flange | ASTM A105 | ASTM A182 |

| Steel Frame | ASTM A587 or ASTM A53 grade B | ASTM A312 |

| Steel bend | according to SCH 40 | |

| Steel bend | one fixed flange, one loose flange | |

| Liner | PFA ( Fluoropolymer ) Lining |

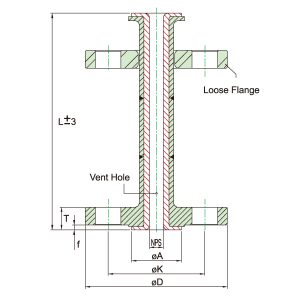

Dimensions

| NPS | L/min. | L/max. | ANSI B16.5 Class 150 | |||||

| INCH | φA | φK | φD | nxφh | T | f/PFA | ||

| 1/2” | 100 | 6000 | 32 | 60.5 | 89 | 4×16 | 14.2 | 3.0 |

| 3/4” | 100 | 6000 | 40 | 69.9 | 98.6 | 4×16 | 14.2 | 3.0 |

| 1” | 100 | 6000 | 48 | 78.2 | 108 | 4×16 | 14.2 | 3.0 |

| 1 1/2” | 100 | 6000 | 69 | 98.6 | 127 | 4×16 | 17.3 | 3.0 |

| 2” | 100 | 6000 | 87.9 | 120.7 | 152.4 | 4×19 | 18.8 | 3.0 |

| 2 1/2” | 100 | 6000 | 100.6 | 139.7 | 77.8 | 4×19 | 21.7 | 4.1 |

| 3” | 100 | 6000 | 127 | 152.4 | 190.5 | 4×19 | 23.2 | 4.1 |

| 4” | 100 | 6000 | 153.2 | 190.5 | 228.6 | 4×19 | 28.0 | 4.1 |

| 6” | 100 | 6000 | 212.7 | 241 | 279 | 8×22 | 29.4 | 4.1 |

UNIT: mm

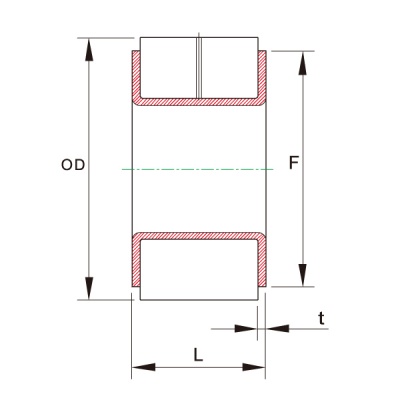

Construction Drawing