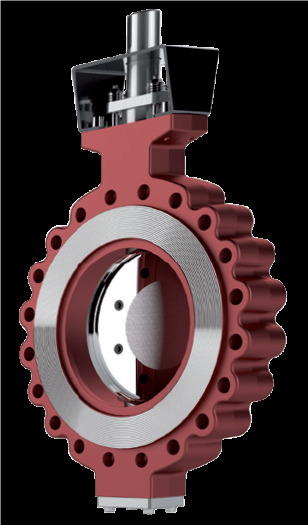

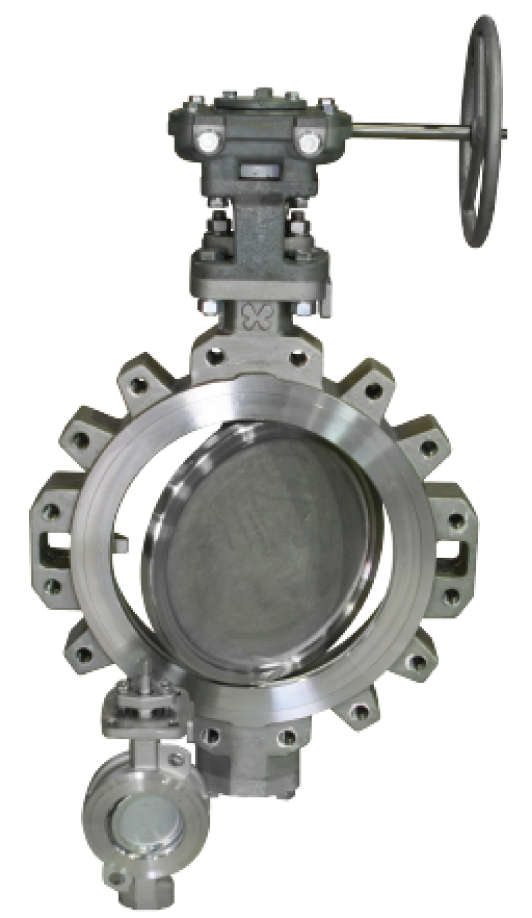

Double Offset High Performance Butterfly Valve – HIPPO

Specifications

Testing:API 598, ISO 5208

Pressure-Temperature Rating:API 609

Valve Design:ASME B16.34, MSS-SP-68

Anti-Blow-Out Stem:API 609

Facc-to-Face:API 609, MSS-SP-68, ISO 5752

Fire Safe:API 607

Low Fugitive Emission Gland Packing System :DIN3780, MSS-SP-143

Marking:MSS-SP-25, API 609

Top Mounting:ISO 5211

Suitable Flange:ANSI 150lb, 300lb,

DIN:PN10, 16, 20, 25, 40, 50

JIS: 10K, 16K, 20K, 30K, 40K

Design Features

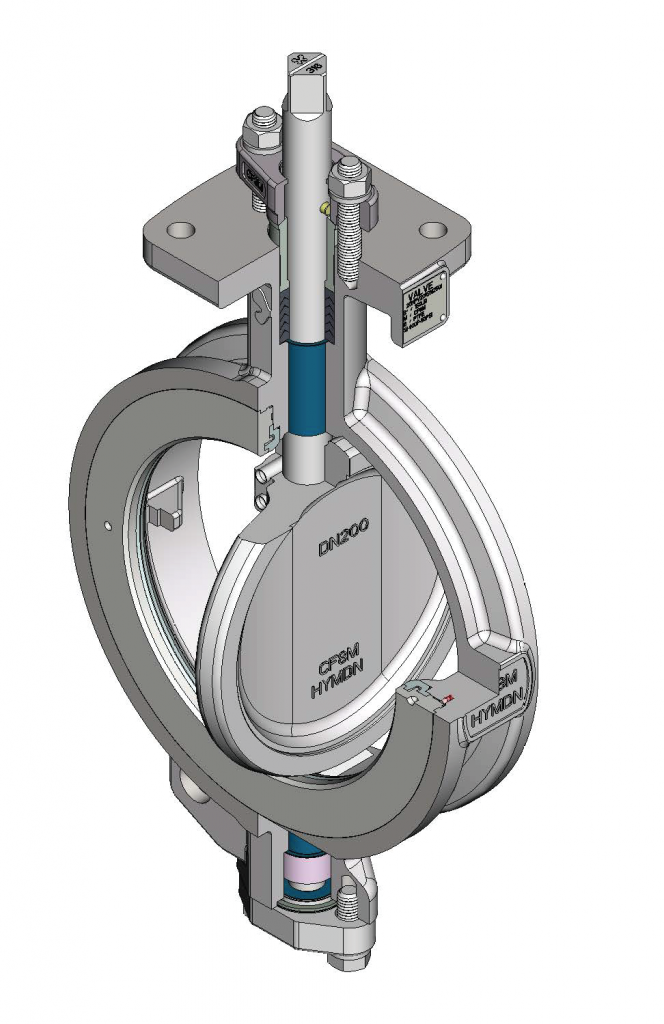

Gland Flange :A fully adjustable two-piece gland flange to make sure an even packing load over 360 °

Gland Flange :A fully adjustable two-piece gland flange to make sure an even packing load over 360 °

Anti-Blow-Out Stem : Protecting stem blow-out caused by pressure.

Gland Bush : Standing alone with Gland Flange, preventing uneven down-pressure on gland packing.

Gland Packing : Use PTFE or same as Valve Seat. Performance is compliance with API 598’s

testing pressure.

Valve Seat : Bi-direction zero leakage design. Use Higa-PTFE, RTFE, or UHMWPE

Taper Pin : Tangentially positioned half in disc and half in stem to

eliminate potential of failure.

Patented Retainer Ring : A no-screw-floating degin to elimate cold flow. This deign

provides positive tight shut-off of seat. Surface roughness is

125-200AARH

Thrust Ring : Use 316 as material. Position in bottom of stem for preventing

incorrect stem shift.

Bottom Cover : Use rigid 316 as material to prevent abnormal leakage

Bottom Gasket : Use RTFE or GRAPHITE as material.

Valve Stem : Use stainless-steel with hard chrome plated. A strong and rigid

one-piece-stem design which largely increase overall strength.

Stem and corresponding components size are all compliance

with ISO 5211. Stem material and disc position is marked on the

top of stem.

Self-Lubrificant Bush : Use PTFE+316 as material to lower down stem’s friction factor.

Valve Disc : Use stainless-steel with hard chrome plated. A

streamlined design with great enhancement on

lowering noise and turbulence.

Valve Body :Compliance with API 609 & ASME B16.34. In order to make valve context

intuitive and straightforward, an additional name plate is designed to mark

detail information.

Lock Pin and Spring :Use PTFE. While Reatiner Ring moves to locking position, spting will

pop-up and push pin locked in Reatiner Ring.

Thrust Plate : Use stainless-steel 316+PTFE to reduce operating friction between

Use RTFE or GRAPHITE as material. stem and bottom cover.