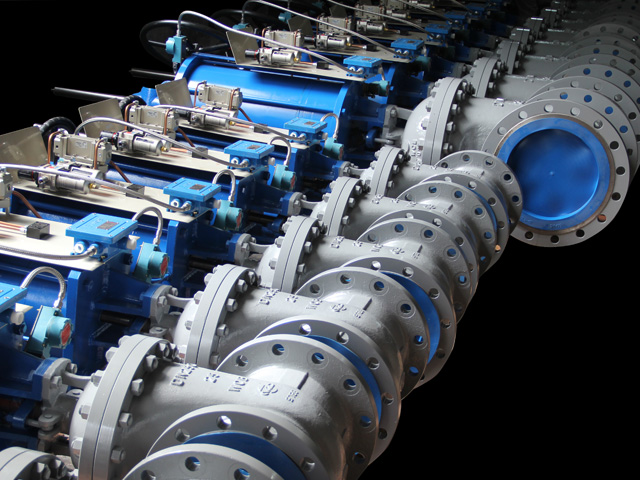

Angle Pattern Slurry Valve – Wuzhou Valves

MAIN FEATURES

The inlet and outlet passageways of the angle pattern control valve are not in the same direction but forming a 90° angle. This kind of control valve can allow the medium flowing through the valve to change its flowing direction. It refers to the valve realizing adjustment of medium flow and pressure by changing the flowing area.

The valves are widely used in chemical fertilizer, mining, metallurgy, aluminum oxide and other industries.

Design Features

- Design standard as per: BS1873、GB/T 12235

- Cone valve discs

- Sealing surface adopts line sealing, ensuring reliable tightness.

- Erosion-proof and corrosion-resisting

- Full Stellite or Tungsten carbide overlay seat sealing surface

- Use flexible and woven graphite collaboration type packing.

Product Range

- Body material: carbon steel, stainless steel, alloy steel

- Nominal diameter:1/2″~24″(DN15~DN600)

- Pressure range: Class150~2500(PN10~PN420)

- End connection: RF, RTJ, BW

- Working temperature:-29℃~560℃

- Operation: handwheel, gear box, electric, etc.