SKIDeX® – Range of skids for pumping/injection of additives in oil storage

MAIN FEATURES:

SKIDeX® Is an easy-to-use stand-alone solution for additives injection,). These skids are robust, reliable and economic specially designed for your injection and additive control solutions, from your storage tanks to your loading arms.

- Connexion to your existing additives tank

- Connexion multi- loading arms

| Additives typical | Concentration | Number of loading arms connected with flow rate 120m3/h |

| FT50BT | 0.1% | 20 |

| Colorant rouge | 0.02% | 100 |

| 9041XF | 0.04% | 50 |

| AC 1209 | 0.105% | 20 |

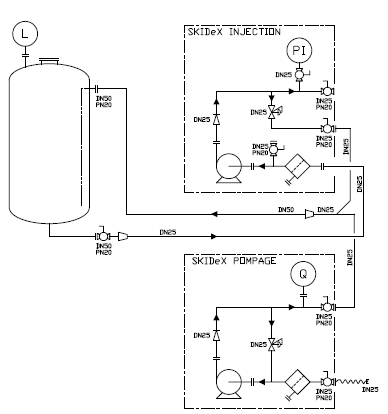

PID

Design Features

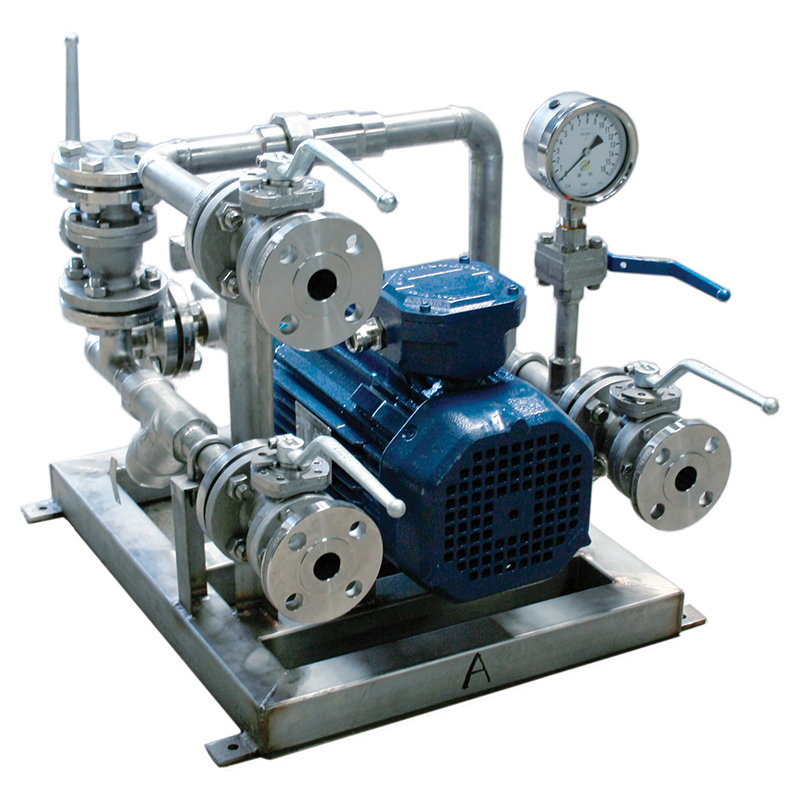

Skid for pumping or injection

- Construction according ATEX area zone I.(II2G Exd IIB T4Gb IP55 Ta 40°c IC411 CLF CATII2G GAZ).

- Flow rate 2.3 m3/h à 10 bars. Multi- Connection to several loading arms simultaneously.

- In-ground tank suction -4m for medium density 1.

- Pump, Valves & Piping Components SS 316L , PTFE & Viton seals.

- Compact design.

- MTBF (Mean Time Between Failure) > 10 years

Product Range

Standard Design :

- Pump 316 SS/ viton seals

- Ball valves 316L SS

- Check valves 316L SS

- Spiral tube ( flexible) 316L SS on request

- Seals PTFE

- Connexion flanges DN 25 class 10lbs RF

| Le SKIDeX® INJECTION | Pump flow | In-ground tank suction

|

| Type SKIDeX-01 | 2,3 m3/H | -4m |

On request

Case of high corrosive additives ( MTBE….)

- Piston volumetric pump or mono-diaphragm Teflon pump

- Magnetic drive gear pump

- Fluor polymer Seals (Kalrez®, Chemraz®…)

Produits similaires