PFA Lined Stainless Steel Ball Valves – PB31 – PN16 – Bueno

Specifications

- Size Range : 1/2″~4″

- Pressure grade : PN16

- Operating temperature : -29°C~+160°C

- Valve body design : ASME B16.42

- Maximum operating pressure : 16bar (232psi)

- 2~3 mm of thickness for PFA lining

- Joints : Flange EN1092-1

- Face to face : EN558-1

- PED – CE certificated

- Tight Fit between PFA liner and stainless body throudh dovetail design

- Double sealing valve body design

- Easy automation with ISO 5211 acuator mounting pad►Application

- Industrial Inorganic Chemicals

- Industrial Organic Chemicals

- Alkali’s & Chlorine

- Detergent production

- Bromine production

- Nitrogenous & Phosphorus Fertilizers

- Pharmaceutical preparation

- Petroleum refining

- Metal & Mining industry

- Plant Protective Agent production

- Pulp, Paper

- Water Treatment

- Sulfur recovery

- Food processing

- Sugar industry

- Corn industry

- HVAC – Heating, ventilation and air confitioning

- Petrochemical

- Semi-conductor

Material List

MATERIALS LIST

| Designation | Material (ASTM) |

| BODY | EN-10213-4/1.4308+PFA (Fluoropolymer) LINER |

| CAP | EN-10213-4/1.4308+PFA (Fluoropolymer) LINER |

| BALL | EN-10213-4/1.4308+PFA (Fluoropolymer) LINER |

| SEAT | TFM1600 |

| STEM | 304 SS+PFA (Fluoropolymer) LINER |

| HANDLE | CF8 |

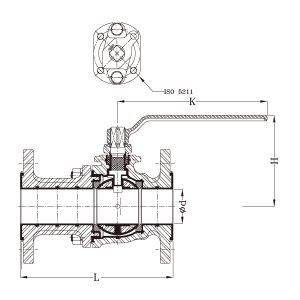

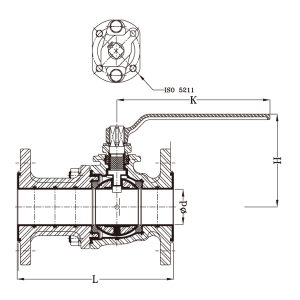

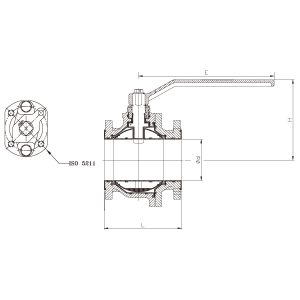

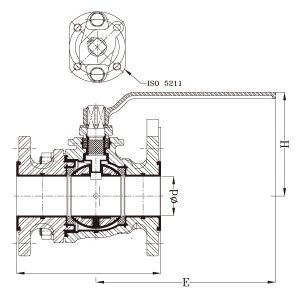

Dimensions

Dimension

| SIZE | L | Ød | H | K |

| DN15 | 130 | 15 | 81 | 145 |

| DN20 | 150 | 20 | 83 | 145 |

| DN25 | 160 | 25 | 98 | 165 |

| DN40 | 200 | 40 | 124 | 225 |

| DN50 | 230 | 50 | 132 | 225 |

| DN65 | 290 | 65 | 164 | 350 |

| DN80 | 310 | 80 | 173 | 365 |

| DN100 | 350 | 100 | 229 | 400 |

Unit : mm

STATIC CV VALUE of PB-31

| SIZE | DN 15 | DN 20 | DN 25 | DN 40 | DN 50 | DN 65 | DN 80 | DN 100 |

| PB-31 | 16 | 35 | 75 | 200 | 310 | 513 | 800 | 1250 |

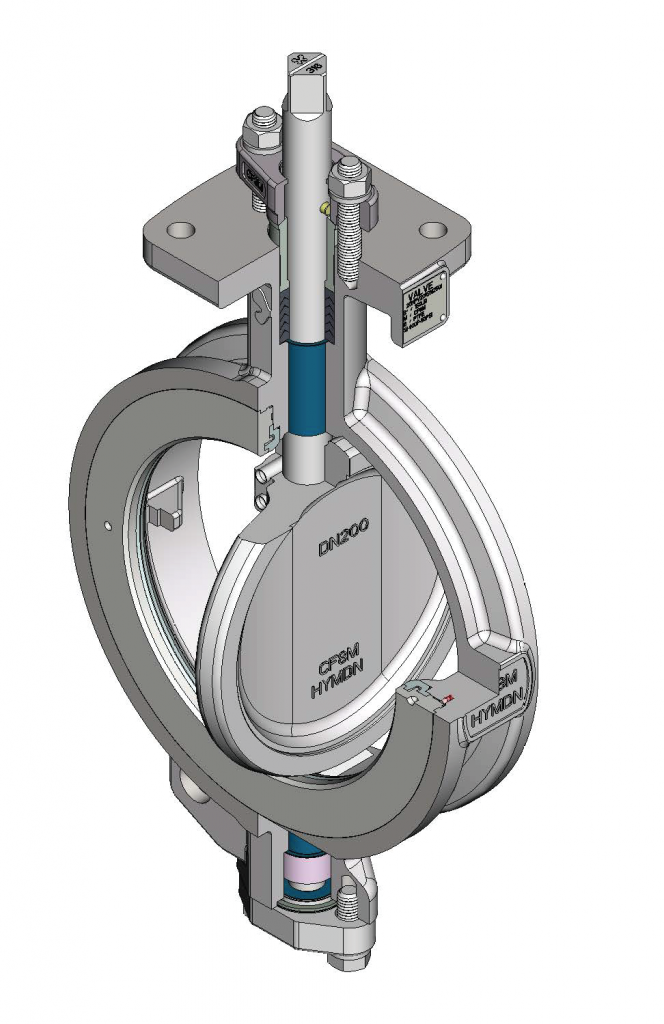

Construction Drawing

Gland Flange :A fully adjustable two-piece gland flange to make sure an even packing load over 360 °

Gland Flange :A fully adjustable two-piece gland flange to make sure an even packing load over 360 °